Core Competence

PRIMARY

TURNING LEAF INTO FINISHED CUT-RAGS

In manufacturing cut rags, the process basically converts tobacco leaves that arrive in cases into batches of cut rag that is ready to be made into cigarettes. All tobacco leaves that are delivered to the factory are checked for quality and carefully processed together with other ingredients that a brand recipe may call for.

The special feature of our factory is the Cut- Rolled Expanded Stems (CRES) line. CRES reduces the cigarette weight while preserving the natural tobacco taste. It also has the ability to increase the filling power and burn rate which in turn reduces the number of puffs as well as reduces the tar and nicotine deliveries per cigarette.

We purchase tobacco leaves from internationally recognized tobacco manufacturers coming from the countries of Zimbabwe, Brazil, Croatia, China, Malawi, Indonesia and USA to ensure its quality. During manufacturing, the tobacco ingredients comprising of the flavor and the blending process play a vital role. Moisture content is checked every critical line of the production while required parameters must be achieved.

The primary lines basically converts leaves into cutrags from primary silo to Secondary Making Machine.

THE PRIMARY PRODUCTS

PROCESSED CUT-RAGS

May be a variance of Processed Virginia or Burley cut-rags and are made and delivered depending on the clients’ needs.

CRES

commonly known as Cut-Rolled Expanded Stem, CRES finished products are also made as the Primary Department’s product.

THE THREE PRIMARY LINES

VIRGINIA LINE

Used almost entirely in cigarette blends. (Characterized by a high sugar to nitrogen ratio).

BURLEY LINE

Burley is light air-cured type Burley is used primarily in cigarette blends. (Characterized by low sugar content and a very low sugar to nitrogen ratio).

CRES LINE

CRES reduces the cigarette weight while preserving the natural tobacco taste. It also has the ability to increase the filling value and burn rate which in turn reduces the number of puffs as well as reduces the tar and nicotine deliveries per cigarette.

THE THREE BLENDS

AMERICAN BLEND

tobacco recipe which may be composed of Virginia, Burley and CRES.

VIRGINIA BLEND

tobacco recipe made primarily of Virginia Tobacco.

CUSTOMIZED BLENDS

depending on the clients’ request, our Research and Development team may create and customize blends/

SECONDARY

WHERE CIGARETTES ARE MANUFACTURED

We aim to create excellent cigarettes for our clients. We have a team of blenders who are on a mission to develop flavors and blends that are client-preferred and top of the line. The development and design of cigarettes with the best tastes is guided by the principles of ISO 9001:2015. Our commitment to innovation is embedded in the use of high-quality raw materials to ensure that our products are consistent in taste and aroma.

Secondary Products

FILTER RODS

FILTER RODS

CIGARETTES

The Molins Octave Super Slims & The Molins Alto

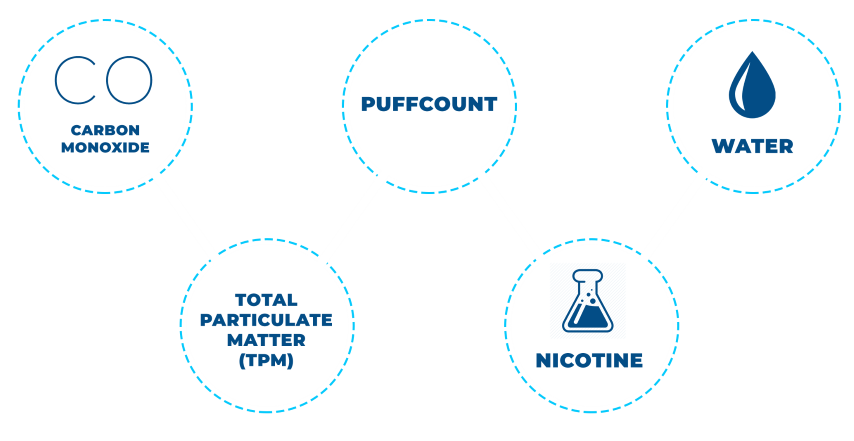

RESEARCH & DEVELOPMENT

OUR COMMITMENT TO EXCELLENCE!

The analytical laboratory of PDMC strives to provide the highest quality, efficiency and reliable service by adhering to international standards. It is geared to gain accreditation for ISO 17025 in the coming years.

OPERATIONAL EXCELLENCE

Achieving Higher Levels of Performance - EVERYDAY!

We at PDMC are committed to build relationships that generate mutual, long-term success for all our stakeholders. We do this by working together to earn the respect and trust of our customers which means a clear focus on adding value to our products through excellent customer service.

In order to achieve operational excellence, we strive everyday to continually improve our processes to ensure that our products remain continue to meet the stringent requirements of our clients.